For all inquiries, please fill in the form below(* are required) to send us a brief message, and we will get back to you as soon as possible.

Gas Pipe Network Inspection System

Ⅰ Market background

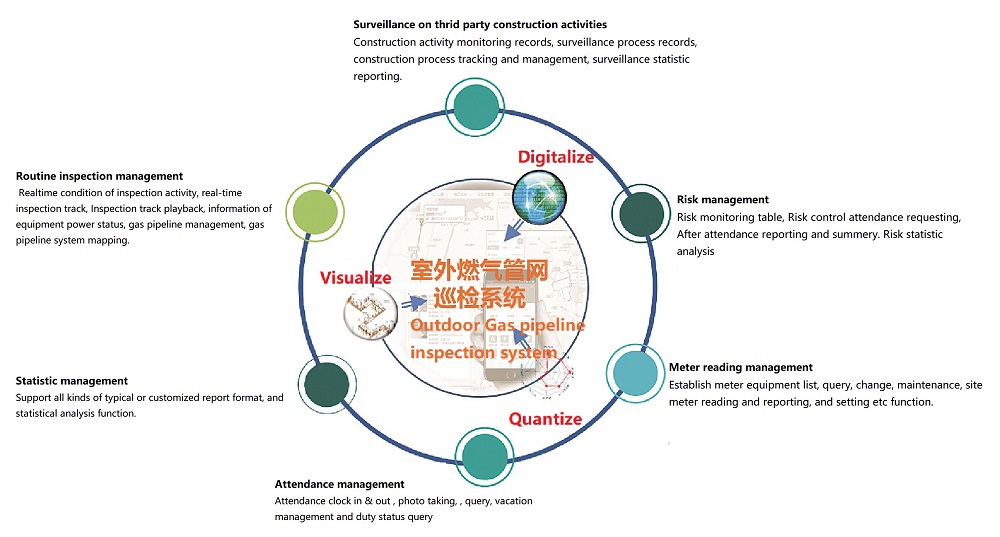

Outdoor gas pipe network inspection system is mainly based on the application of GPS, GIS, GPRS inspection management system. The system closely integrates the GIS information of the gas pipeline network and its ancillary facilities with the pipeline network leak detection equipment and inspectors, which can quickly provide real and accurate gas pipeline network data, and can achieve rapid leak detection, real-time data uploading, regional division, real-time Trajectory, precise positioning and other functions provide a reliable and scientific basis for the daily management, analysis and statistics, and safety prediction of the outdoor gas pipeline network.

Ⅱ System composition

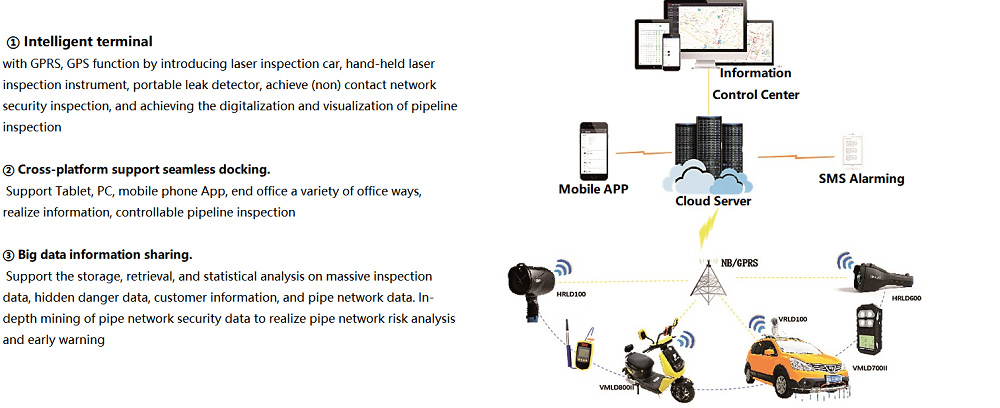

2.1 System Architecture Diagram

2.2 System Composition

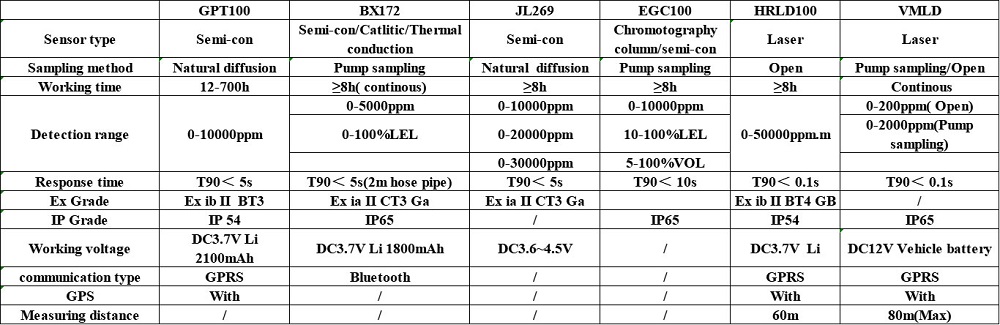

2.2.1 Gas pipeline inspection equipment

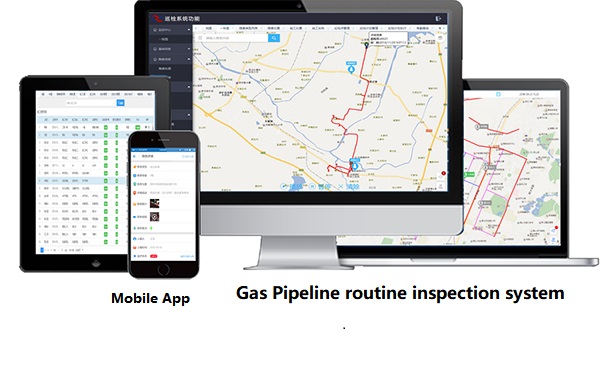

2.2.2 Gas pipe network inspection system

This system integrates advanced technologies such as GIS, Bluetooth, GPRS, GPS and the Internet of Things. Through the application of various intelligent inspection terminals, combined with GIS pipe network information, the visualization, digitization and quantification of pipe network inspection are realized, so as to effectively ensure the daily safety of the pipeline network facilities, improve the reliability of gas transmission, and ensure the minimum failure rate of the gas pipeline network.

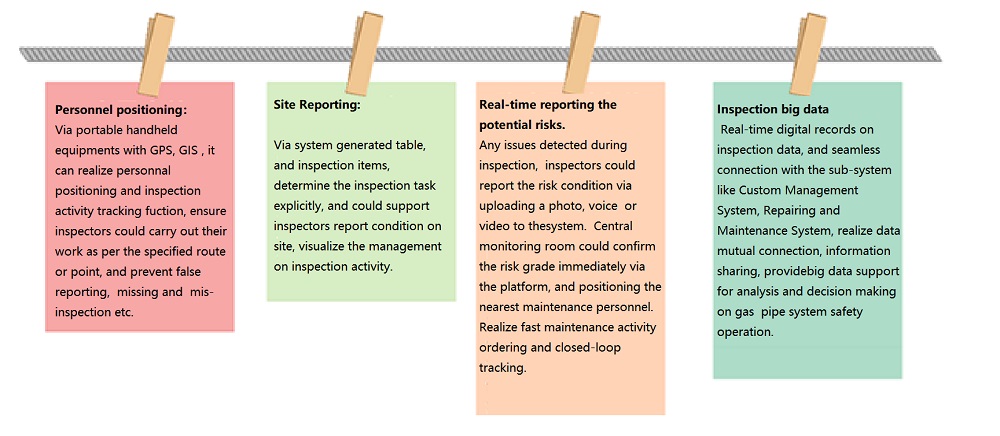

3.Main Function:

1) One GIS map: Based on the GIS information of the gas pipeline network or on the basis of free maps such as Baidu, the grid management of the pipeline network inspection area, the location of leaks/hidden dangers, and the tracking of personnel/vehicles can be realized;

2) Pipe network equipment management: complete the basic information maintenance of pipe network leak detection equipment, and establish equipment life cycle files;

3) Pipe network inspection management: It mainly completes the formulation of various reports, assignment of tasks, collection and storage of various data, and control and management of the business flow process in the entire business process of inspection, maintenance, and emergency repair scheduling;

4) Scheduling management: View the location of nearby inspectors through the platform, quickly assign tasks, and traceable management of hidden dangers;

5) Report management: realize various inspection record reports, statistical analysis reports, etc., support information display in the form of graphics and tables, and support the export function.

4. Main Application scenarios:

5.Advantages & values

System advantage

This system can solve the difficult problems existing in the inspection of the pipeline network of gas enterprises from the following aspects:

1) The work can be quantified: the inspection work is changed from paper to electronic mode, and big data records and storage are formed. It can be seen at a glance from the platform on Inspectors' attendance records, inspection mileage, the number of hidden safety hazards found, the number of emergencies handled and the completion effect.

2) Visualization of the effect: real-time upload of gas concentration data at each inspection point, on-site evidence taking, photographing and video recording of abnormal/hidden points, support for voice input for on-site situation explanation, real-time positioning of personnel, and real-time tracking of trajectories.

3) The process can be traced back: the scheme supports the function of quick dispatch of hidden dangers. For sudden abnormal/hidden accidents, orders can be quickly dispatched to the nearest emergency repairing personnel, and the processing results can be reported for feedback. Realize the traceability of pipe network security incidents.

4) Scientific management: Through the realization of the above functions, the humane and casual inspection management in the traditional mode is eliminated, so that the inspection management work is well-documented and evidence-based.

System value